The global cleanroom technology market, particularly the critical segment of air showers, is experiencing a robust surge, signaling an unprecedented expansion in global semiconductor manufacturing capabilities. Valued at approximately USD 7.69 billion in 2024 and projected to reach USD 10.82 billion by 2030, the broader cleanroom market is growing at a significant CAGR of 5.9%. More specifically, the semiconductor cleanroom market is set to expand even faster, from USD 8.08 billion in 2025 to USD 11.88 billion by 2030, at an impressive CAGR of 8.0%. This escalating demand underscores the industry's relentless pursuit of ultra-clean environments, indispensable for producing the next generation of advanced microchips.

Air showers, serving as the frontline defense against particulate contamination, are a cornerstone of this growth. With the global air shower market, estimated at USD 5.50 billion in 2023, expected to reach USD 7.30 billion by 2029, their indispensable role in maintaining the pristine conditions required for modern chip fabrication is undeniable. This vigorous expansion is directly tied to the explosive global demand for advanced semiconductors powering AI, IoT, 5G, electric vehicles, and high-performance computing, all of which necessitate increasingly complex and miniaturized chips produced in environments where even microscopic particles can cause catastrophic defects.

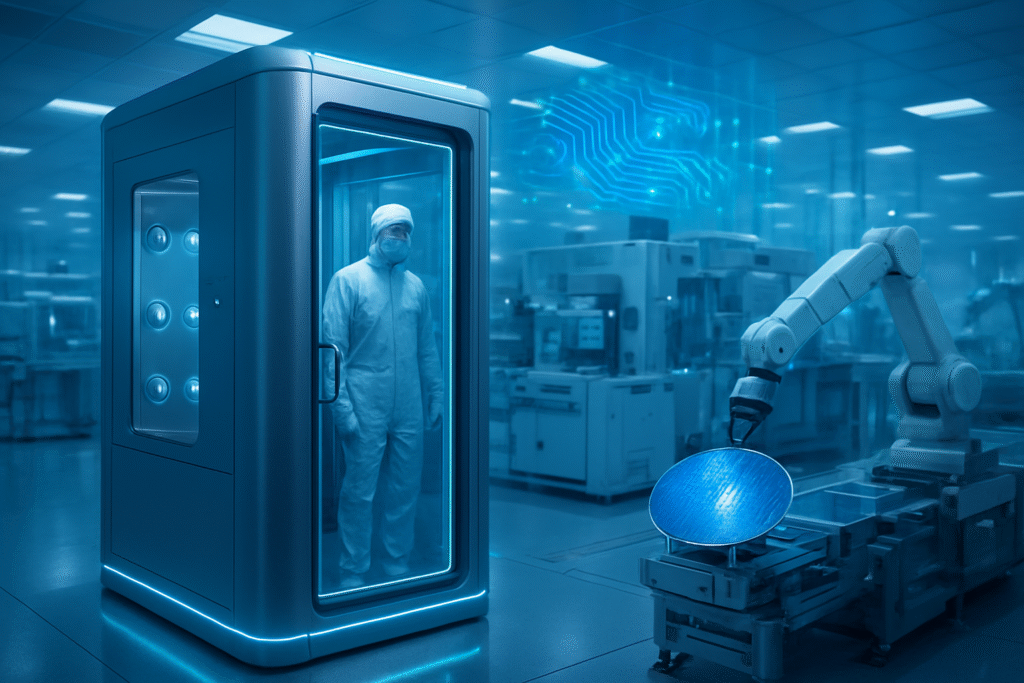

The Unseen Guardians: How Air Showers Enable Precision Manufacturing

At the heart of advanced semiconductor manufacturing lies the meticulous control of environmental contamination. Air showers are purpose-built transition chambers positioned at the entry points of cleanrooms, acting as a crucial barrier between less clean areas and the ultra-sensitive fabrication zones. Their function is deceptively simple yet profoundly effective: to forcefully remove particulate matter from personnel and materials before they enter critical processing areas. This is achieved through high-velocity jets of HEPA (High-Efficiency Particulate Air) or ULPA (Ultra-Low Penetration Air) filtered air, which effectively dislodge dust, skin flakes, and other mobile contaminants from cleanroom garments.

These systems are vital for achieving and maintaining the stringent ISO cleanroom classifications (ee.g., ISO Class 1-5) mandated for advanced semiconductor processes such as photolithography, where even a single 0.3-micron particle can render a microchip unusable. Unlike passive contamination control methods, air showers actively decontaminate, significantly reducing the human-borne particulate load. Modern air showers often integrate smart controls, energy-saving features, and advanced filtration, representing a continuous evolution from simpler designs to highly sophisticated, automated systems that align with Industry 4.0 principles in semiconductor fabs, enhancing operational efficiency and minimizing human interaction.

The semiconductor industry's consensus is clear: air showers are not merely supplementary equipment but a fundamental requirement for achieving high wafer yields and ensuring device reliability. Their efficacy directly translates into reduced product defects and significant cost savings, as contamination-related yield losses can be staggeringly expensive, with production downtime potentially exceeding $500,000 per hour. This makes the investment in advanced air shower technology a critical component of profit protection and quality assurance for chip manufacturers worldwide.

A Tailwind for Cleanroom Innovators and Chipmakers Alike

The accelerating growth in cleanroom technology and air showers presents a significant boon for a specialized cohort of companies. Manufacturers of cleanroom equipment and integrated solutions, such as Cleanroom Technology Holdings Ltd. (HKG: 02337) and Terra Universal, Inc. (Privately held), stand to benefit immensely from the increased demand for new fab construction and upgrades. Similarly, companies specializing in air shower systems, like Airtech Japan, Ltd. (TYO: 6291) or M+W Group (part of Exyte AG, Privately held), will see expanded market opportunities.

For major semiconductor manufacturers such as Taiwan Semiconductor Manufacturing Company (TSMC) (NYSE: TSM), Samsung Electronics Co., Ltd. (KRX: 005930), and Intel Corporation (NASDAQ: INTC), the availability of advanced cleanroom infrastructure is not just a competitive advantage but an operational imperative. These companies are investing billions in new fabrication plants globally, and the robust growth in cleanroom technology ensures they can meet the stringent environmental demands of cutting-edge chip production. This development reinforces the strategic advantage of regions with strong cleanroom supply chains, potentially influencing future fab location decisions.

While not a disruption to existing products, the advancements in cleanroom technology enable the disruption of previous manufacturing limitations. By facilitating the production of smaller, more complex chips with higher yields, these technologies empower semiconductor companies to push the boundaries of innovation. The competitive landscape will likely see increased R&D into more energy-efficient, modular, and AI-integrated cleanroom solutions, as companies vie to offer the most cost-effective and high-performance contamination control systems.

The Foundation of a New Silicon Age

The surging market for cleanroom technology and air showers is more than just a niche trend; it's a foundational element of the broader global semiconductor expansion, underpinning the very fabric of the emerging "Silicon Age." This growth directly supports geopolitical initiatives like the U.S. CHIPS and Science Act and similar efforts in Europe and Asia, aimed at bolstering domestic chip production and supply chain resilience. Without advanced cleanroom capabilities, the ambitious goals of these initiatives would be unattainable.

The impacts are far-reaching: higher volumes of advanced chips will fuel innovation across industries, from more powerful AI models and pervasive IoT devices to safer autonomous vehicles and faster 5G networks. This proliferation of cutting-edge technology will, in turn, drive economic growth and enhance global connectivity. However, this expansion also brings potential concerns, primarily the immense capital expenditure required for state-of-the-art cleanroom facilities and their significant energy consumption. The demand for highly specialized talent to design, operate, and maintain these complex environments also presents a challenge.

In comparison to previous milestones, the current focus on cleanroom technology echoes past breakthroughs in lithography or material science that enabled successive generations of chip miniaturization. Just as advancements in steppers and reticles were crucial for moving from micron-scale to nanometer-scale manufacturing, the sophisticated evolution of cleanroom environments, including air showers, is now indispensable for pushing into sub-5 nanometer nodes and advanced packaging technologies. It highlights a fundamental truth in semiconductor manufacturing: the environment is as critical as the process itself.

The Horizon: Smarter, Greener Cleanrooms

Looking ahead, the trajectory for cleanroom technology and air showers points towards increased integration with smart factory concepts and sustainability initiatives. Near-term developments are expected to include more sophisticated IoT sensors for real-time environmental monitoring, coupled with AI-powered analytics for predictive maintenance and optimized contamination control. This will allow for more dynamic adjustments to air flow, filtration, and personnel entry protocols, further enhancing efficiency and yield.

Long-term, modular cleanroom designs are gaining traction, offering greater flexibility and scalability for rapid deployment and adaptation to evolving manufacturing needs. There will also be a strong emphasis on energy efficiency, with innovations in HVAC systems, fan filter units, and air shower designs aimed at reducing the substantial power footprint of these facilities. Experts predict a continuous drive towards fully automated cleanroom environments, minimizing human intervention and thereby reducing the primary source of contamination.

The challenges remain significant: maintaining ultra-low contamination levels as chip features shrink further, managing the escalating costs of construction and operation, and developing greener technologies will be paramount. Nevertheless, the relentless pace of semiconductor innovation ensures that the cleanroom technology sector will continue to evolve, finding new ways to create the pristine conditions essential for the microchips of tomorrow.

The Unseen Foundation of Tomorrow's Tech

The escalating market growth of cleanroom technology, particularly air showers, stands as a clear and compelling indicator of the vigorous expansion underway in global semiconductor manufacturing. This isn't merely an ancillary market; it's the fundamental enabler for the production of the advanced microchips that power our increasingly digital world. The relentless demand for semiconductors, driven by emerging technologies, necessitates an equally relentless pursuit of pristine manufacturing environments.

The significance of this development cannot be overstated. It underscores the critical role of contamination control in achieving high yields and quality in chip fabrication, directly impacting the availability and cost of everything from smartphones to supercomputers. As major chipmakers invest unprecedented sums in new fabs across the globe, the cleanroom industry, with air showers at its vanguard, is proving to be an indispensable partner in this ambitious undertaking.

In the coming weeks and months, industry watchers should keenly observe continued investment trends in cleanroom infrastructure, innovations in energy-efficient designs, and the integration of AI and automation into contamination control systems. These developments will not only shape the future of semiconductor manufacturing but also determine the pace at which next-generation technologies permeate our lives. The humble air shower, often overlooked, is in fact a powerful symbol of humanity's ongoing quest for precision and progress.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.