What Is Polyolefin Blown Film Extrusion?

Polyolefin blown film extrusion is widely used to produce packaging films for food, consumer goods, industrial liners, agricultural films, and protective packaging.

Modern blown film production increasingly requires thin gauge films, high output rates, smooth surface quality, and stable long-term extrusion.

To achieve these goals, processors commonly use LLDPE, mLLDPE, LDPE, and metallocene polyolefins, which place higher demands on extrusion processability.

Typical Processing Challenges in Blown Film Extrusion

As production speed increases and film thickness decreases, blown film manufacturers frequently encounter:

× Melt fracture (sharkskin) at high line speeds

× Poor melt flow and unstable bubble behavior

× Severe die build-up and frequent cleaning

× Increased torque and extrusion pressure

× Strong reliance on fluorinated PPA processing aids

These issues limit output efficiency, surface appearance, and operational stability.

Why Fluorinated PPAs Are Being Replaced in Blown Film Applications?

Fluorinated polymer processing aids have traditionally been used to improve melt flow and suppress melt fracture.

However, growing PFAS regulatory pressure, particularly in packaging and food-contact applications, is driving the industry toward fluorine-free alternatives.

Blown film producers are increasingly required to balance:

• High-speed extrusion performance

• Regulatory and sustainability compliance

• Long-term formulation reliability

SILIKE PFAS-Free PPA Solution for Blown Film Extrusion

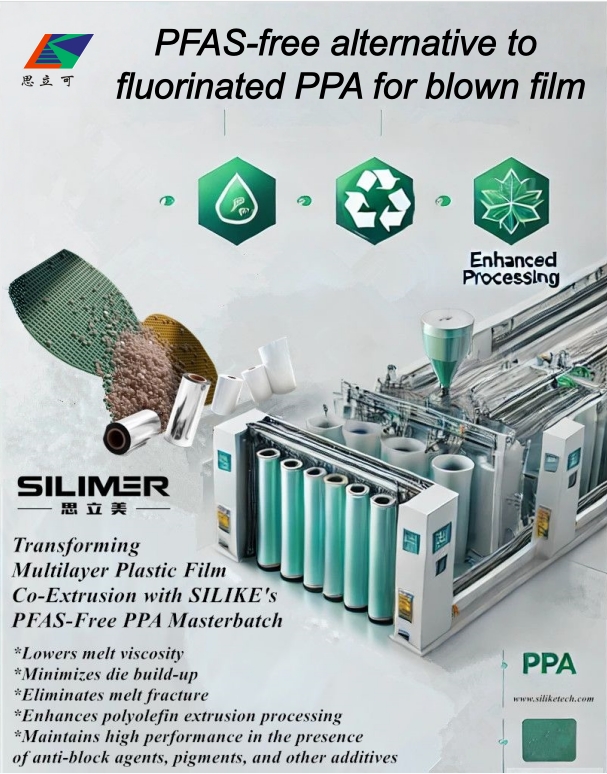

SILIKE SILIMER PFAS-Free PPA Masterbatch is a fluorine-free processing aid developed for polyolefin extrusion, including blown film applications.

With a low addition level, SILIMER helps processors achieve stable, high-output extrusion without PFAS.

Key Benefits of SILIKE PFAS-free processing aids in Blown Film Extrusion:

√ Improved melt flow and processing stability

√ Effective elimination of melt fracture (sharkskin)

√ Reduced die build-up and longer cleaning intervals

√ Lower extrusion torque and pressure

√ Smooth and uniform film surface quality

Typical Applications

• Polyolefin blown films (PE / LLDPE / mLLDPE)

• Thin-gauge packaging films

• Food and industrial packaging

• Agricultural and protective films

Why Choose SILIKE as a PFAS-free PPA Supplier?

With over 20 years of expertise in silicone-modified polymer additives, SILIKE offers PFAS-free processing solutions customized to address the challenges of modern blown film extrusion. If you are seeking an alternative to fluorinated PPA, contact amy.wang@silike.cn to obtain our Blown film processing aid – Fluorine-free processing aid. Or, visite Website: www.siliketech.com to learn more about SILIMER PFAS and fluorine-free alternative solutions!

Blown Film Processing FAQ (PFAS-Free PPA)

Question: How can melt fracture be eliminated in blown film extrusion?

Answer:

Melt fracture in blown film extrusion is caused by high shear stress at the die wall, particularly at high output rates.

Using a polymer processing aid that reduces melt-to-die friction is an effective solution.

Many processors now use PFAS-free PPAs, such as SILIKE SILIMER SILIKE SILIMER Fluorine-free PPA, to eliminate melt fracture while maintaining regulatory compliance.

Question: Why are processing aids necessary in modern blown film lines?

Answer:

Modern blown film production requires thinner films and higher output, often using mLLDPE and metallocene polyolefins.

These materials improve strength but reduce processing stability, making processing aids essential for consistent extrusion.

Question: What is the best PFAS-free alternative to fluorinated PPA in blown film extrusion?

Answer:

PFAS-free PPAs based on silicone-modified polymer technology are widely used as alternatives.

SILIKE SILIMER PFAS-Free PPA is designed for polyolefin blown film extrusion and provides stable, high-output performance.

Question: Do PFAS-free PPAs affect blown film mechanical properties?

Answer:

No. Properly formulated PFAS-free PPAs do not negatively impact film strength, sealing performance, or appearance.

Media Contact

Company Name: Chengdu Silike Technology Co.,Ltd.

Email: Send Email

Country: China

Website: https://www.siliketech.com/