From premium architectural panels to stainless steel enclosures, manufacturers are turning to V-grooving to achieve cleaner bends, sharper lines, and more consistent surface quality—without sacrificing throughput.

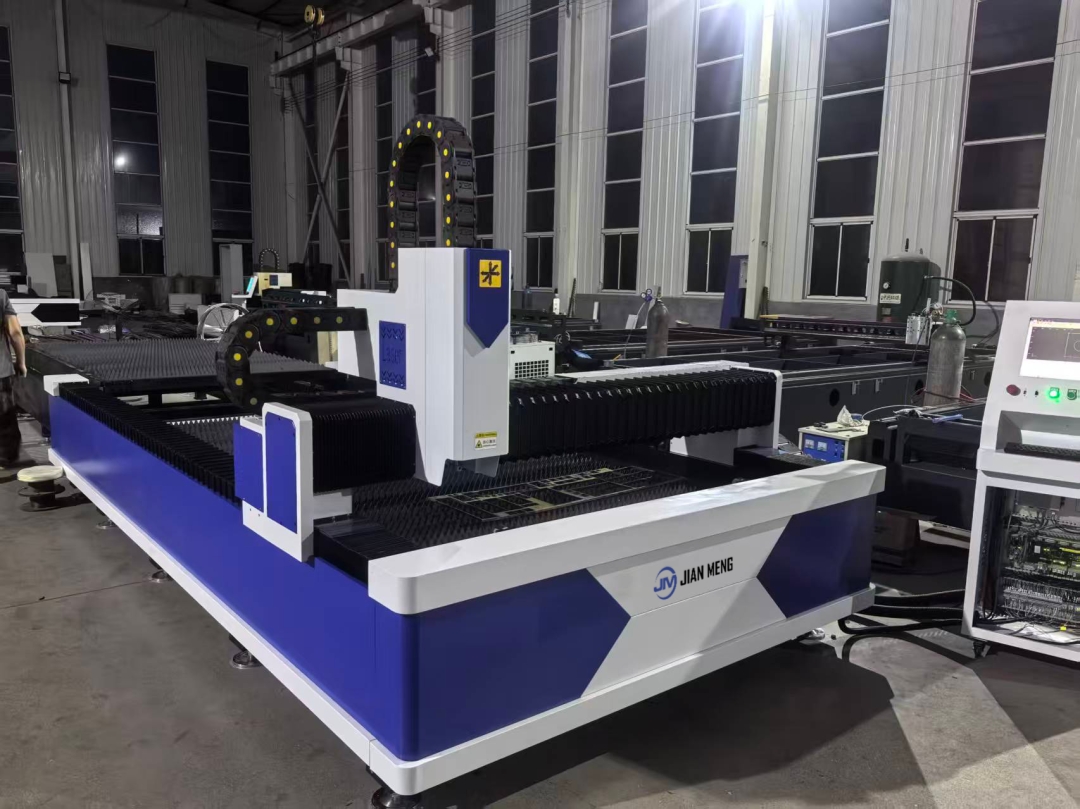

In today’s competitive fabrication landscape, buyers are no longer choosing equipment based on capacity alone. They are choosing based on what the finished part looks like, how consistently it performs in assembly, and how efficiently it moves through the production line. Jianmeng Intelligent Equipment (Taizhou) Co., Ltd., a manufacturer focused on sheet metal fabrication machinery, is responding to these demands with integrated solutions centered on the V grooving machine—helping metalworking businesses improve bend accuracy, reduce surface defects, and elevate the visual quality of high-value sheet metal products.

The Pain Point Buyers Know Too Well: “The Bend Looks Fine… Until It Doesn’t”

For fabricators working with stainless steel, decorative panels, elevator cladding, architectural metal, and premium cabinets, bending quality is not a “nice-to-have.” It’s the difference between a product that looks high-end and a product that gets rejected.

Common issues include:

-

Unstable bend lines and inconsistent appearance across batches

-

Surface cracking, whitening, or distortion when bending thicker or harder materials

-

Visible bend radius that ruins sharp-edge design requirements

-

Rework caused by burrs, micro-defects, and poor edge preparation

-

Low efficiency from frequent setup adjustments and trial bends

A V grooving machine addresses these problems at the process level by creating controlled grooves on the sheet before bending. This supports sharper, cleaner bends with less stress on the material—often improving both aesthetics and consistency.

Why V Grooving Is Becoming a “Must-Have” Step in Premium Fabrication

V-grooving has grown rapidly in popularity because it solves two big manufacturing contradictions: customers want sharper bends and cleaner surfaces, but production teams want fewer rejects and faster cycles.

By grooving the bending line precisely, a V grooving machine can help:

-

Reduce bending force requirements and improve bend predictability

-

Improve the visual sharpness and uniformity of finished parts

-

Support demanding design trends in architectural and decorative stainless steel

-

Improve downstream bending efficiency when paired with a press brake

-

Stabilize output quality for repeatable production and easier inspection standards

For many buyers, the goal is simple: make the first part right, and make every part after that look identical.

JIAN MENG’s One-Line Advantage: Process Coverage, Not Single Machines

While the V grooving machine is the headline solution, JIAN MENG positions it within a wider workflow approach. Modern buyers often prefer suppliers that can support multiple stages of fabrication—because integration reduces compatibility risk, training cost, and long-term service complexity.

JIAN MENG’s main product portfolio covers key sheet metal processes, including:

-

V grooving machine and V-cutting solutions

-

Press brake options (including electric press brake configurations) for precise bending

-

Shearing machine systems for accurate cutting and material preparation

-

Deburring machine solutions to improve edge quality and reduce rework

-

Forming solutions for shaping and fabrication versatility

-

Notching and related equipment for production flexibility

This “process coverage” is especially valuable for buyers building a complete production line or upgrading multiple steps at once—where consistency and reliability across operations matter as much as individual machine performance.

Turning Quality Demands Into Competitive Advantage

For procurement teams and plant managers, machine selection is ultimately a business decision. A premium part finish can justify a higher selling price—while stable production reduces hidden costs that rarely appear on a purchase order.

A complete, quality-focused sheet metal workflow can help businesses:

-

Reduce scrap rates and rework time

-

Improve on-time delivery by stabilizing production output

-

Increase customer satisfaction through consistent appearance and fit

-

Shorten training time with standardized operation logic across machines

-

Strengthen long-term profitability by controlling quality at the source

“A growing number of customers want sharper design lines and better surface integrity, especially in stainless steel decorative applications,” said a spokesperson at JIAN MENG. “Our goal is to help fabricators achieve that premium finish consistently—while maintaining efficiency and reliability on the shop floor.”

Built for Buyers Who Care About Real-World Production

Buyers evaluating a V grooving machine are often balancing multiple requirements: accuracy, stability, ease of operation, and long-term service support. In real factories, the best machine is the one that produces consistent parts with minimal downtime and predictable maintenance needs.

JIAN MENG emphasizes practical value through:

-

Engineering-driven machine design for stable, repeatable performance

-

Production-oriented configurations suitable for daily manufacturing environments

-

Support for different fabrication needs—from decorative panels to industrial enclosures

-

Flexible customization options based on material type, thickness range, and workflow goals

-

A product lineup that complements upstream and downstream steps (cutting, deburring, bending)

This approach is especially relevant for companies producing stainless steel panels, architectural trim, elevator interiors, metal cabinets, equipment housings, and other applications where clean edges, consistent bends, and refined surface appearance are critical.

A Smarter Way to Upgrade: Choose the Workflow, Not Just the Equipment

For manufacturers upgrading from conventional bending-only processes, the shift to V-grooving is often motivated by one fact: customers are becoming more demanding, and tolerances—both dimensional and visual—are getting tighter.

In many cases, adding a V grooving machine can also improve results from existing bending equipment. When combined with a CNC press brake, V-grooving supports a more controlled bend line and can reduce the trial-and-error that slows down production, especially on premium materials.

Meanwhile, pairing grooving with a deburring machine helps fabricators control edge conditions and reduce finishing labor—further stabilizing appearance and assembly fit.

About JIAN MENG

JIAN MENG specializes in sheet metal fabrication machinery, providing equipment and solutions that support efficient, precise, and stable metal processing workflows. With a product range covering V-grooving, bending, shearing, deburring, and forming processes, the company serves manufacturers seeking consistent quality, improved productivity, and dependable equipment performance for modern fabrication demands.

Media Contact

Company Name: Jianmeng Intelligent Equipment (Taizhou) Co., Ltd.

Email: Send Email

Phone: +86 19805122954

Address:299 Tongchuang Road, Zhangqiao Town

City: Taizhou

State: Jiangsu

Country: China

Website: https://www.jianmeng.com