Established in 1998 and based in Quanzhou, Fujian Province, Fujian Jinqiang Machinery Manufacturing Co., Ltd. has emerged as a leading high-tech enterprise in China’s fastener industry. Specializing in a comprehensive range of products—including wheel bolts and nuts, center bolts, U-bolts, bearings, and spring pins—Jinqiang offers end-to-end services spanning production, processing, logistics, and export. Yet, what truly distinguishes the company in a competitive global market is its uncompromising commitment to quality inspection: every fastener leaving its facilities undergoes rigorous testing, with only those meeting stringent standards reaching customers.

In an industry where even the smallest component can impact safety—whether in automotive assembly, construction machinery, or aerospace applications—Jinqiang’s quality control protocols are not just procedures but a core philosophy. “A bolt or nut might seem insignificant, but its failure can have catastrophic consequences,” explains Zhang Wei, Jinqiang’s Quality Assurance Director. “That’s why we’ve built a multi-layered inspection system that leaves no room for error.”

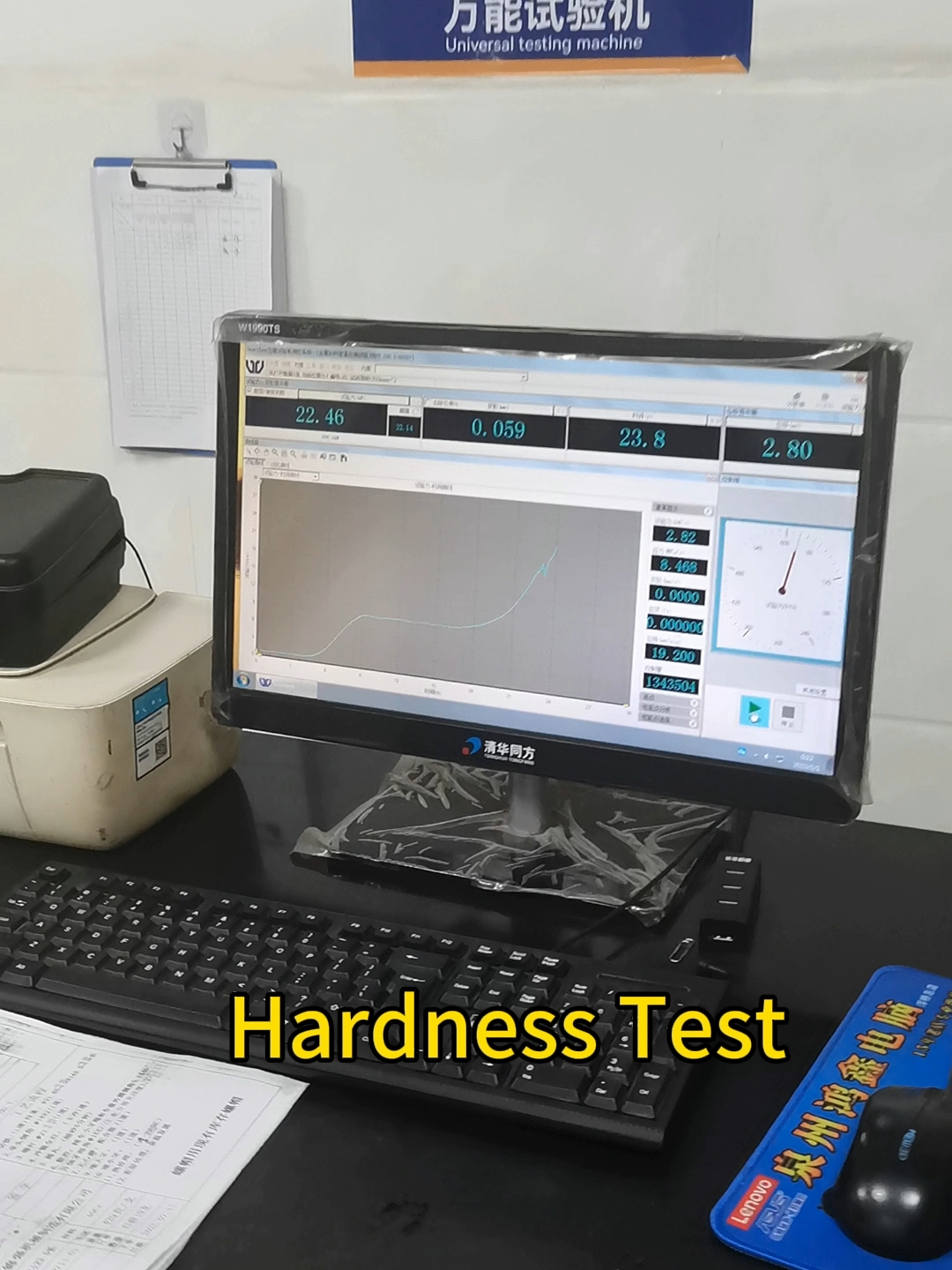

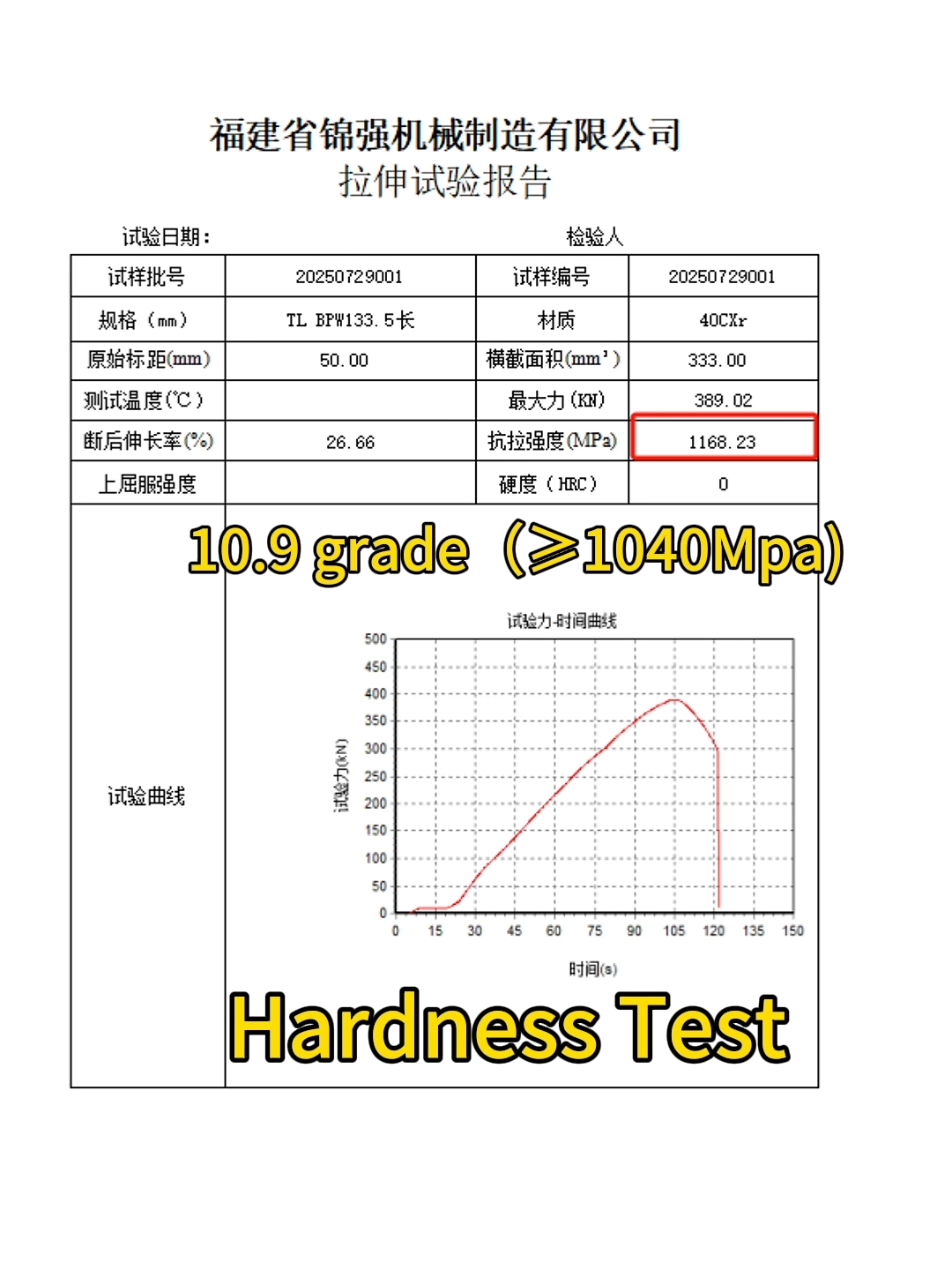

The process begins long before production. Raw materials—primarily high-grade alloy steels and stainless steels—are subjected to exhaustive checks upon arrival. Samples are tested for tensile strength, ductility, and resistance to corrosion using advanced spectrometers and hardness testers. Only materials that meet international benchmarks, such as those set by ISO and ASTM, are approved for manufacturing. This focus on raw material integrity ensures that the foundation of every fastener is sound.

During production, precision is paramount. Jinqiang employs state-of-the-art CNC machining centers and automated forging equipment, which operate with tolerances as tight as ±0.01mm. Real-time monitoring systems track variables like temperature, pressure, and tool wear, alerting operators to even minor deviations that could affect quality. Each batch is assigned a unique traceability code, allowing teams to track every step of production—from forging to threading to heat treatment—ensuring full accountability.

Post-production, the most rigorous phase begins. Every fastener undergoes a battery of tests designed to simulate real-world conditions. Threads are inspected for uniformity using digital gauges, while load tests measure a bolt’s ability to withstand torque without breaking or stripping. Salt spray tests assess corrosion resistance, exposing samples to harsh environments for up to 1,000 hours to ensure they can endure extreme weather or industrial settings. For critical components like wheel bolts, additional fatigue tests are conducted, subjecting them to repeated stress to mimic the demands of long-haul transportation or heavy machinery operation.

“Our inspectors are trained to be meticulous—if a fastener is even 0.1mm out of specification, it’s rejected,” notes Zhang. Rejected items are not discarded haphazardly but analyzed to identify root causes, whether in machinery calibration, material composition, or human error. This data-driven approach feeds into continuous improvement initiatives, allowing Jinqiang to refine processes and reduce defects further.

This dedication to quality has earned Jinqiang certifications from global authorities, IATF 16949 (for automotive components) . More importantly, it has fostered trust among clients worldwide. From leading automotive OEMs in Europe to construction firms in Southeast Asia, customers rely on Jinqiang not just for timely delivery but for the certainty that every fastener will perform as expected.

“Our export partners often tell us that Jinqiang’s products reduce their own inspection costs because they know what arrives is already perfect,” says Li Mei, head of Jinqiang’s Export Division. “That trust translates to long-term partnerships—many of our clients have worked with us for over a decade.”

Looking ahead, Jinqiang plans to enhance its quality control capabilities with the integration of AI-powered inspection systems. These technologies will automate visual checks, using high-resolution cameras and machine learning algorithms to detect flaws invisible to the human eye, further speeding up the process without compromising accuracy. The company is also investing in green manufacturing practices, ensuring that its quality standards extend to sustainability—reducing waste in rejected items and optimizing energy use in testing facilities.

In a market flooded with low-cost, low-quality alternatives, Fujian Jinqiang Machinery Manufacturing Co., Ltd. stands firm in its belief that quality is non-negotiable. For over 25 years, it has proven that excellence is not achieved by chance but by design—through rigorous inspection, unwavering standards, and a commitment to protecting the safety of those who depend on its products. As Jinqiang continues to expand its global footprint, one thing remains constant: every fastener it ships is a promise kept.

Media Contact

Company Name: Jinqiang Machinery Manufacture Co., Ltd.

Email: Send Email

Country: China

Website: https://www.jqtruckparts.com/