Cellulose ethers (HEC, HPMC, MC, etc.) and redispersible polymer powders (typically based on VAE, acrylates, etc.) are two crucial additives in mortars, especially dry-mix mortars. They each possess unique functions, and through clever synergistic effects, they significantly enhance the overall performance of the mortar. Their interaction is primarily manifested in the following aspects:

Cellulose ethers provide key environments (water retention and thickening):

Water retention: This is one of the core functions of cellulose ether. It can form a hydration film between mortar particles and water, significantly reducing the rate of water evaporation to the substrate (such as porous bricks and blocks) and air.Impact on redispersible polymer powder: This excellent water retention creates crucial conditions for redispersible polymer powder to function: Providing film-forming time: polymer powder particles need to be dissolved in water and redispersed into emulsion.

The polymer powder then coalesces into a continuous, flexible polymer film as the water gradually evaporates during the mortar drying process. Cellulose ether slows water evaporation, giving the polymer powder particles ample time (open time) to evenly disperse and migrate into the mortar pores and interfaces, ultimately forming a high-quality, complete polymer film. If water loss is too rapid, the polymer powder will not fully form a film or the film will be discontinuous, significantly reducing its reinforcing effect.

Ensuring Cement Hydration: Cement hydration requires water. The water-retention properties of cellulose ether ensure that while the polymer powder forms the film, the cement also receives sufficient water for full hydration, thereby developing a good foundation for early and late strength. The strength generated by cement hydration combined with the flexibility of the polymer film is the foundation for the improved performance.

Cellulose ether improves workability (thickening and air entrainment):

Thickening/Thixotropy: Cellulose ethers significantly increase the consistency and thixotropy of mortars (thick when still, thinning when stirred/applied). This improves the mortar's resistance to sag (slipping down vertical surfaces), making it easier to spread and level, resulting in a better finish.Air entraining effect: Cellulose ether has a certain air entraining ability, introducing tiny, uniform and stable bubbles.Impact on polymer powder:Improved dispersion: Appropriate viscosity helps latex powder particles disperse more evenly in the mortar system during mixing and reduces agglomeration.Optimized workability: Good construction properties and thixotropy make mortar containing latex powder easier to handle, ensuring that it is evenly applied to the substrate, which is essential for fully exerting the bonding effect of latex powder at the interface.Lubrication and cushioning effects of air bubbles: The introduced air bubbles act as ball bearings, further improving the lubricity and workability of the mortar. Simultaneously, these microbubbles buffer stress within the hardened mortar, complementing the toughening effect of the latex powder (although excessive air entrainment can reduce strength, so a balance is necessary).

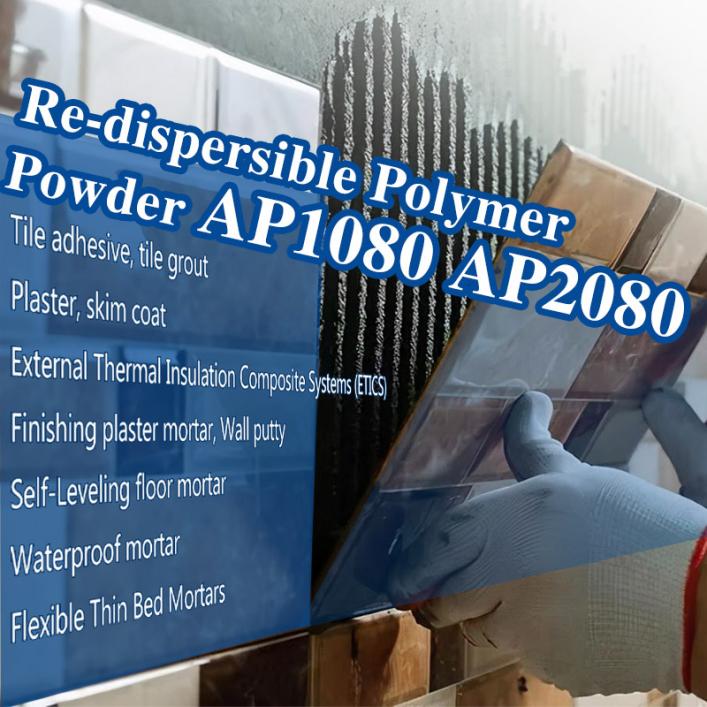

Redispersible polymer powder provides flexible bonding and reinforcement (film formation and bonding):

Formation of polymer film: As mentioned earlier, during the drying process of the mortar, the latex powder particles aggregate into a continuous three-dimensional polymer network film.Impact on mortar matrix:Enhanced cohesion: The polymer film wraps and bridges cement hydration products, unhydrated cement particles, fillers and aggregates, significantly enhancing the bonding force (cohesion) between the components within the mortar.Improved flexibility and crack resistance: The polymer film is inherently flexible and ductile, giving the hardened mortar greater deformation capacity. This enables the mortar to better absorb and distribute stresses caused by temperature changes, humidity changes, or slight displacements of the substrate, significantly reducing the risk of cracking (cracking resistance).Improved impact resistance and wear resistance: The flexible polymer film can absorb impact energy and improve the impact resistance and wear resistance of the mortar.Lowering the elastic modulus: making the mortar softer and more adaptable to deformation of the substrate.

Latex powder improves interfacial bonding (interface enhancement):

Supplementing the active area of cellulose ethers: The water-retention effect of cellulose ethers also reduces the problem of "interfacial water shortage" caused by excessive water absorption by the substrate. More importantly, polymer powder particles/emulsions have a tendency to migrate to the mortar-substrate interface and the mortar-reinforcement fiber (if any) interface.Forming a strong interface layer: The polymer film formed at the interface strongly penetrates and anchors into the substrate's micropores (physical bonding). Simultaneously, the polymer itself exhibits excellent adhesion (chemical/physical adsorption) to a variety of substrates (concrete, brick, wood, EPS/XPS insulation boards, etc.). This significantly enhances the mortar's bond strength (adhesion) to various substrates, both initially and after immersion in water and freeze-thaw cycles (water resistance and weather resistance).

Synergistic optimization of pore structure and durability:

Effects of cellulose ether: Water retention optimizes cement hydration and reduces loose pores caused by water shortage; air entraining effect introduces controllable tiny pores.Effect of polymer powder: The polymer membrane partially blocks or bridges the capillary pores, making the pore structure smaller and less connected. Synergistic Effect: The combined effect of these two factors improves the mortar's pore structure, reducing water absorption and increasing its impermeability. This not only enhances the mortar's durability (freeze-thaw resistance and salt corrosion resistance), but also reduces the likelihood of efflorescence due to reduced water absorption. This improved pore structure is also associated with higher strength.Cellulose ether is both the "foundation" and "guarantee": it provides the necessary water-retention environment (enabling cement hydration and latex powder film formation), optimizes workability (ensuring uniform mortar placement), and influences the microstructure through thickening and air entrainment.Redispersible latex powder is both the "enhancer" and "bridge": it forms a polymer film under the favorable conditions created by the cellulose ether, significantly improving the mortar's cohesion, flexibility, crack resistance, bond strength, and durability.Core synergy: The water-retention capacity of cellulose ether is a prerequisite for the effective film formation of latex powder. Without sufficient water retention, latex powder cannot fully function. Conversely, the flexible bonding of latex powder offsets the brittleness, cracking, and insufficient adhesion of pure cement-based materials, significantly enhancing durability.

Combined effects: The two enhance each other in improving pore structure, reducing water absorption, and enhancing long-term durability, resulting in synergistic effects. Therefore, in modern mortars (such as tile adhesives, exterior insulation plaster/bonding mortars, self-leveling mortars, waterproof mortars, and decorative mortars), cellulose ethers and redispersible polymer powders are almost always used in pairs. By precisely adjusting the type and dosage of each, high-quality mortar products can be designed to meet diverse performance requirements. Their synergistic effect is the key to upgrading traditional mortars into high-performance polymer-modified cementitious composites.

Media Contact

Company Name: LONGOU INTERNATIONAL BUSINESS (SHANGHAI) CO., LTD

Email: Send Email

Country: China

Website: https://www.longoucell.com/