SENTHAI Carbide Tool Co., Ltd., a US-invested manufacturer with over 21 years of expertise in carbide wear parts, today announced the official launch of its latest Carbide Snow Plow Blade product line. This new series is designed to provide significantly longer service life, enhanced wear resistance, and reduced maintenance downtime for snow removal operations worldwide.

The announcement comes as SENTHAI strengthens its global market strategy by introducing advanced carbide snow plow solutions tailored for both commercial fleets and municipal snow management agencies. The company’s move marks a key expansion into regions where extreme winter conditions demand high-performance cutting edges.

New Carbide Snow Plow Blade Line Delivers 10× Longer Life

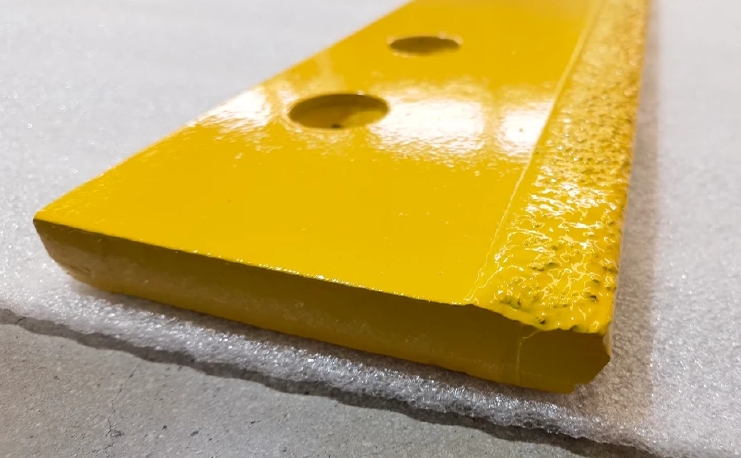

SENTHAI’s newly released carbide snow plow blades feature tungsten carbide particle cladding, offering a service life at least ten times longer than traditional carbon steel blades. The enhanced durability reduces the frequency of blade replacements, which translates into fewer interruptions, lower labor costs, and greater operational efficiency for snow removal teams.

The standard blade design is a 3/4-inch thick metal plate with a single carbide insert brazed into the face. This construction provides a strong balance between abrasion resistance and impact protection, ensuring reliable performance when cutting through ice and compacted snow on the first pass.

“Our carbide snow plow blades are engineered to meet the most demanding environments,” said SENTHAI’s product director. “By integrating tungsten carbide inserts into the blade structure, we deliver exceptional wear resistance and a consistent cutting edge that dramatically extends service life.”

Customizable Sizes and Tungsten Inserts for Diverse Applications

SENTHAI offers a full range of standard sizes and customizable options to meet the needs of different snow plow configurations. The carbide cutting edges can be mounted on the front, underbody, and wing of snow plows depending on the application.

Unlike traditional steel cutting edges that wear out quickly and require frequent replacement, SENTHAI’s carbide blades are built to withstand high abrasion and impact. The company reports that carbide blades can extend snow plow blade life up to 10 to 20 times compared with conventional steel cutting edges.

In addition, SENTHAI provides various sizes of tungsten inserts and supports custom manufacturing to suit unique requirements. This flexibility allows customers to choose the most effective solution for their specific snow removal conditions.

Quality Assurance Through Full Control of the Manufacturing Process

SENTHAI’s product quality is supported by its fully automated production lines in Rayong, Thailand, which include wet grinding, pressing, sintering, welding, and vulcanization workshops. Each stage is rigorously controlled to ensure consistent performance and superior bonding strength between carbide inserts and steel blades.

The company is certified under ISO9001 and ISO14001, confirming compliance with international manufacturing and environmental standards.

“Stable factory quality is the foundation of our business,” said the company’s operations manager. “By managing the entire production process in Thailand—from R&D and engineering to final assembly—we ensure fast response times, reliable delivery, and consistent product performance.”

New Market Strategy: Global Expansion and Strategic Partnerships

Alongside the product launch, SENTHAI is implementing a new market strategy to strengthen its presence in key winter markets. The company currently supplies products to more than 80 global partners, and the new carbide snow plow blade line is expected to drive growth in North America, Europe, and other regions with severe winter conditions.

SENTHAI’s global expansion strategy includes enhanced customer support and faster delivery through efficient production planning and stock management. The company also emphasizes partnerships with distributors and OEMs, enabling broader access to high-quality carbide wear parts for snow plows and road maintenance fleets.

Looking Ahead: New Rayong Production Base in 2025

To support growing demand, SENTHAI will launch a new production base in Rayong in late 2025. The expanded facility will increase manufacturing capacity and strengthen innovation capabilities, ensuring SENTHAI remains a leading supplier of carbide snow plow blades and road maintenance wear parts.

“Our new production base will enable us to meet higher demand while maintaining strict quality control,” said the company’s CEO. “We are committed to providing cost-effective and dependable carbide tools that support the evolving needs of the global snow removal industry.”

About SENTHAI

SENTHAI Carbide Tool Co., Ltd. is a US-invested manufacturer based in Rayong, Thailand, specializing in snow plow blades and road maintenance wear parts. With over two decades of experience, SENTHAI produces a wide range of products, including JOMA Style Blades, Carbide Blades, I.C.E. Blades, and Carbide Inserts. The company’s fully automated production lines and strict quality assurance processes ensure high performance and long service life.

For more information or to request a quotation, SENTHAI invites interested customers to contact their sales team for detailed product catalogs and customized solutions.

Media Contact

Company Name: SENTHAI

Email: Send Email

Country: China

Website: https://www.senthaitool.com/